Advanced Manufacturing Investment Surges as Industry 4.0 and 5.0 Reshape Global Production

Across the global manufacturing landscape, a new wave of investment is signaling a decisive shift toward automation, robotics, and artificial intelligence. Major companies – including Rockwell Automation and Toyota – are expanding or restructuring facilities specifically to integrate advanced digital capabilities. This marks a pivotal moment: manufacturing is transitioning from traditional operational models into the fully connected, data-driven realities of Industry 4.01 and the emerging Industry 5.02.

The Current State of Industry 4.0

At the heart of the surge is a recognition that factories of the future must be smarter, more efficient, and more resilient. Industry 4.0 technologies, such as autonomous robotics, industrial IoT3 sensors, advanced analytics, and real-time machine learning, have moved from optional enhancements to operational necessities. These technologies enable manufacturers to detect issues before they occur, optimize throughput using live data, reduce strain on human-workers, and build agile production systems capable of responding to supply-chain shocks4. As global volatility continues – from fluctuating demand cycles to geopolitical disruptions – companies are doubling down on systems that reinforce operational stability.

Manufacturers Paving the Way

A prime example is Rockwell Automation’s new manufacturing campus planned for southeast Wisconsin, expected to be one of the largest in the company’s history. The facility is being designed around next-generation automation equipment and digitally connected production lines. By focusing on smart-factory principles from the ground up, Rockwell aims to accelerate domestic industrial-equipment production while showcasing what a model Industry 4.0 facility can achieve: higher productivity, lower downtime, and dynamic responsiveness to customer needs.

Similarly, Toyota’s recent $912 million investment across several U.S. plants underscores how deeply the automotive sector is embracing advanced manufacturing. As Toyota increases hybrid-vehicle production, it is simultaneously modernizing plants with automation, robotics, and digital quality-control systems. This combination reflects a broader trend in transportation manufacturing: the shift to electrification requires new production methods, more rigorous testing, and sharper energy-efficiency targets – all well-suited to automated, sensor-driven environments.

The Emergence of Industry 5.0

However, the rise of Industry 5.0 adds an additional layer. Where Industry 4.0 emphasizes machine-to-machine intelligence, Industry 5.0 centers on collaboration between humans and smart systems. Rather than replacing workers, tomorrow’s manufacturing environment is expected to pair highly skilled employees with intuitive cobots5, AI-assisted decision-making tools, and augmented-reality training systems. The goal is enhanced safety, more meaningful human roles, and production systems that adapt not just to market conditions, but also to workforce needs.

This blend of automation and human-centric design is reshaping how companies plan expansions. Modern manufacturing facilities are prioritizing flexibility, workforce development, and digital integration from day one. The push toward reshoring6 and regionalizing supply chains has accelerated this shift, as companies seek greater control and visibility over production operations. Smart factories offer exactly that: self-diagnosing equipment, transparent energy usage, and real-time performance dashboards enabling leaders to make faster, data-backed decisions.

Final Thoughts

As investment continues to climb and technology continues to advance, the manufacturing sector is entering a new era – one in which intelligent machines, connected systems, and skilled workers operate side by side to build faster, safer, more adaptive production environments. Companies like Rockwell Automation and Toyota are driving this shift today and setting the blueprint for how goods will be made in the decades to come.

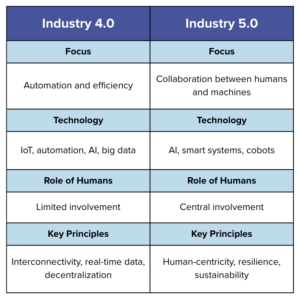

See below for a brief comparison of the existing Industry 4.0 and the emerging Industry 5.0:

Please reach out to a member of our Manufacturing & Distribution team for more information on the topic outlined above. For more information regarding our Manufacturing & Distribution experience, visit our Manufacturing & Distribution industry page.

Definitions

Industry 4.01 – the Fourth Industrial Revolution, where manufacturing becomes smart, connected, and automated through digital technologies.

Industry 5.02 – the next evolution of manufacturing that focuses on human-centered, sustainable, and resilient production, where humans and advanced technologies work together.

Iot3 (aka Internet of Things) – a network of physical devices – like machines, sensors, appliances, vehicles, and tools – that are connected to the internet so they can collect data, share information, and interact automatically.

Supply Chain Shock4 – a sudden disruption that interrupts the normal flow of goods, materials, or production.

Cobot5 (short for collaborative robot) – is a robot designed to work safely alongside humans, sharing the same workspace and assisting with tasks rather than replacing human workers.

Reshoring6 – bringing manufacturing or production back to the company’s home country after it had previously been moved overseas.

About the Author

Camden Hess joined McKonly and Asbury in 2023. He is currently a Supervisor for the firm’s Tax Segment.